■Structure

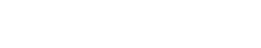

【Furnace Structure】By using a special material for the combustion chamber, this crematorium can shortens the arrival time to 800 ° and the cooling time. With our unique special pan and ceramic mat, the crematorium also shortens the cremation time and suppresses the odor after cremation.

【Emplacement Structure】It is a structure that allows you to pull out the pan from inside the furnace onto the opened door to collect the remains.

【Incineration capacity】Supports up to 30kg (Small animals to mid-sized dogs).

【Fuel】Kerosene

■ Control Panel and Temperature Management

The incineration temperature can be freely controlled with a simple switch operation.

Since you can check the temperature on the digital display, you can cremate according to your wishes:

"I want to keep the remains at a clean state at a lower temperature."

"I want to shorten the cremation time with a higher temperature."

■Compliance with Environmental Measures and Laws

Primary combustion chamber: It is equipped with two burners: main burner and an auxiliary burner for an efficient cremation.

Secondary combustion chamber: By equipping the secondary burner as standard equipment, the unburned gas generated from the primary combustion chamber is efficiently reburned at a high temperature, and the generation of smoke and odor is suppressed to the maximum. It meets all the structural standards of the Waste Disposal and Public Cleansing Law for incinerators.